Leveraging Biomimicry in Industrial Design

Biomimicry is revolutionizing industrial design, offering innovative solutions inspired by nature's time-tested patterns and strategies. This approach is gaining traction across sectors, from aerospace to consumer products, as companies seek sustainable, efficient, and resilient designs. By emulating nature's 3.8 billion years of R&D, industries are uncovering groundbreaking approaches to complex challenges.

The Foundations of Biomimicry in Industry

Biomimicry is rooted in the observation that nature has already solved many of the problems we’re grappling with today. From energy efficiency to waste reduction, natural systems have evolved elegant solutions over millions of years. The core principle of biomimicry in industrial design is to study these natural models and emulate their forms, processes, and ecosystems to create more sustainable and efficient products and systems.

This approach requires a shift in perspective, viewing nature as a mentor rather than just a resource. It involves deep observation and understanding of biological systems, followed by abstraction of principles that can be applied to human design challenges. The result is often innovative solutions that are not only more effective but also more environmentally friendly.

Key Areas of Application

Biomimicry is finding applications across a wide range of industries, each drawing unique insights from nature’s designs:

-

Materials Science: Nature’s materials, like spider silk and abalone shells, are inspiring new, stronger, and more flexible materials.

-

Architecture and Construction: Buildings inspired by termite mounds for natural ventilation or lotus leaves for self-cleaning surfaces.

-

Energy Systems: Solar cells mimicking leaf structures for improved light absorption.

-

Transportation: Vehicle designs inspired by fish and birds for improved aerodynamics and fuel efficiency.

-

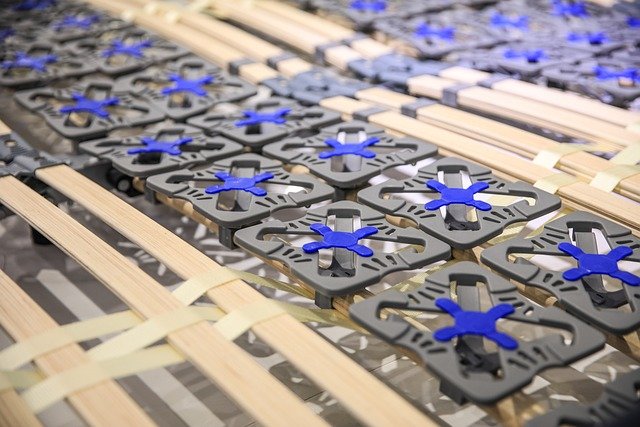

Manufacturing Processes: Production systems that emulate closed-loop natural ecosystems, minimizing waste and maximizing resource efficiency.

Case Studies in Industrial Biomimicry

Several companies have successfully implemented biomimicry principles in their industrial designs:

-

Shinkansen Bullet Train: Engineers in Japan redesigned the nose of the bullet train based on the kingfisher’s beak, significantly reducing noise and improving energy efficiency.

-

Velcro: Inspired by the way burrs stick to dog fur, George de Mestral invented this ubiquitous fastening system.

-

Wind Turbine Blades: Humpback whale fin structures have inspired more efficient wind turbine blade designs, increasing energy output.

-

Self-Cleaning Paints: Lotusan paint, inspired by the lotus leaf’s self-cleaning properties, reduces the need for chemical cleaners and maintenance.

These examples demonstrate how biomimicry can lead to tangible improvements in product performance, efficiency, and sustainability.

Challenges and Considerations

While biomimicry offers immense potential, its implementation in industrial design is not without challenges:

-

Complexity of Natural Systems: Fully understanding and replicating nature’s intricate designs can be difficult and time-consuming.

-

Scale Differences: What works at a biological scale may not always translate directly to industrial applications.

-

Interdisciplinary Collaboration: Effective biomimicry requires collaboration between biologists, engineers, and designers, which can be challenging to orchestrate.

-

Initial Costs: The research and development required for biomimetic solutions can be expensive, though often offset by long-term benefits.

-

Regulatory Hurdles: Novel biomimetic designs may face regulatory challenges in industries with strict safety standards.

Future Prospects and Emerging Trends

The future of biomimicry in industrial design looks promising, with several emerging trends:

-

AI and Machine Learning: These technologies are accelerating the discovery of biomimetic solutions by analyzing vast amounts of biological data.

-

Nano-scale Biomimicry: As nanotechnology advances, we’re seeing more applications of biomimicry at the molecular level.

-

Bioengineering: The line between biomimicry and bioengineering is blurring, with some solutions directly incorporating living organisms into industrial processes.

-

Circular Economy Integration: Biomimicry principles are increasingly being applied to create circular, waste-free industrial systems.

-

Climate Change Adaptation: Nature’s resilience strategies are informing industrial designs to better cope with changing environmental conditions.

Implementing Biomimicry in Your Industry

-

Start with clear problem definition: Identify specific challenges in your industry that could benefit from nature-inspired solutions.

-

Build interdisciplinary teams: Bring together biologists, engineers, and designers to foster innovative thinking.

-

Invest in biomimicry education: Train your team in biomimicry principles and methodologies.

-

Create a biomimicry database: Develop a repository of biological strategies relevant to your industry’s challenges.

-

Prototype and iterate: Test biomimetic designs in real-world conditions and refine based on feedback.

-

Consider lifecycle analysis: Ensure that biomimetic solutions truly offer sustainable improvements over traditional approaches.

-

Engage with biomimicry networks: Collaborate with academic institutions and industry groups focused on biomimicry.

As industries grapple with the need for sustainable, efficient, and resilient solutions, biomimicry offers a powerful framework for innovation. By turning to nature’s 3.8 billion years of evolution, we can uncover designs and strategies that are inherently optimized for our planet’s conditions. The challenge lies in effectively translating these biological insights into practical industrial applications. As more success stories emerge and research deepens, biomimicry is poised to play an increasingly crucial role in shaping the future of industrial design and sustainable business practices.